Thank you for Subscribing to Energy Business Review Weekly Brief

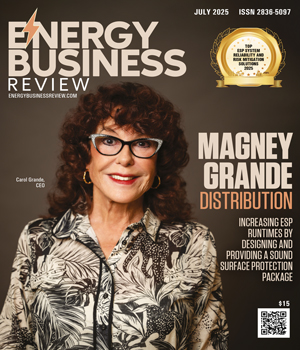

For years, oil producers across West Texas accepted a familiar refrain. Whenever an electric submersible pump (ESP) failed, the cause was deemed mechanical or attributed to unpredictable well conditions, without consideration of electrical phenomenon. But for Magney Grande Distribution CEO Carol Grande, this didn’t add up. When rotors parted, rotor bearings exhibited electrical fluting and motor leads failed, the symptoms pointed to something far less visible. What others dismissed as mechanical failure, Carol Grande delved deeper for a systemic issue, electrical side-effects masquerading as wear and tear. “It was like chasing ghosts. You think it’s metal fatigue or vibration, but what you’re really seeing is misdirected energy,” explains Carol Grande. That investigation led Carol Grande and her team to come up with a comprehensive suite of mitigation technologies, their surface protection package. This package contains an all-mode secondary surge protective device, an enhanced grounding system, and intelligent monitoring through Ziton and the Common Mode Filter. Each of these individual components addresses a range of potential sources of failure and mitigates the potential effects. The technical expertise of Magney Grande and its proven surface protection package has reshaped industry assumptions around ESP failure. The paradigm is shifting from reactive maintenance to a forward-looking model grounded in engineered protection, diagnostic precision and sustained production integrity. Built with Resilience, Engineered for Extremes Carol Grande had seen the pattern before, when lightning storms would routinely disable variable-frequency drives (VFD) in submersible pump systems. But unlike industrial facilities equipped with layered protections, the pumps in remote oilfields operated in isolation, exposed to relentless heat, abrasive dust and unforgiving terrain. The vulnerabilities were amplified and largely unaddressed. Recognizing this gap, Magney Grande designed a new class of surge protective devices, engineered specifically to withstand these punishing conditions. And when producers raised concerns about inadequate grounding in low-conductivity soil, the team responded with a chemical grounding solution that is environmentally safe and effective in dissipating dangerous electrical energy. The real inflection point came when a major oil producer posed a simple question: Why were ESPs running longer on outdated switchboards than on modern VFDs, which were supposed to optimize performance?

Natural Gas Compression Services of the Year 2025

Compression maintains the integrity and efficiency of the natural gas supply chain. Without it, transporting gas from wellheads to processing plants and distribution networks would be impossible. For more than seven decades, Archrock (NYSE: AROC) has perfected this essential service, providing unmatched reliability and performance to the midstream oil and gas market. Archrock has expertly navigated industry shifts and technological evolution to deliver top-tier contract compression and aftermarket services. As the premier provider of natural gas compression in the U.S., it offers comprehensive services that include installation, operation and maintenance of all aspects of gas compression production. Simply stated, it compresses a customer’s tendered gas stream, increasing its pressure for further transportation down the pipe toward final monetization. “Our customers demand an integrated, worry-free gas compression experience that maximizes uptime, and we strive to deliver it without fail,” says Jason G. Ingersoll, Senior Vice President of Sales and Operations Support. Comprehensive Services for Every Need For businesses looking to optimize capital allocation, Archrock’s contract compression service is a cost-effective alternative to purchasing expensive compression equipment and engaging experienced Field Service Technicians to maintain, repair and operate it. Archrock’s offering includes the use of an Archrock-owned all-inclusive compressor package—comprising a driver (engine or motor), a compressor and all other associated equipment—together with the most skilled and trained Field Service Technicians in the industry to help ensure safe and reliable operations, all for a fixed, nominal monthly fee. With contract compression services, customers can redirect capital investment into alternate aspects of their operations, which will bolster their bottom line. Innovative technologies augment Archrock’s world-class technical expertise. By deploying advanced telemetry, remote monitoring and machine learning, Archrock’s system anticipates and helps prevent equipment failures through targeted, preemptive actions. This predictive approach enables maximized, reliable runtimes and empowers customers to be confident that they will be assisted in moving more gas. Maintaining peak performance is non-negotiable in this specialized industry. Archrock’s aftermarket services support the repair needs of businesses that own compression equipment and help them maximize productivity. Its expert operations, maintenance, overhaul and reconfiguration services maintain critical infrastructure in optimal condition, helping to prevent costly disruptions and extending the lifespan of valuable assets..

Energy Management Consulting Firm 2025

Rising energy costs and unpredictable energy markets pose significant challenges for many businesses. Daily fluctuations in natural gas and electricity prices can substantially impact operations and profitability, often overwhelming many companies. Fortunately, experts in the energy management field offer solutions and recommendations geared at helping businesses lower energy costs and provide them with much-needed relief. American Gas & Electric Group LLC (American GEG), a leading North American energy consulting and utility construction management firm, is one of the experts within its field that strives to assist businesses of all sizes facing these types of energy-related challenges. As a respected Christian organization, it provides strategic energy management recommendations to multinational corporations, regional chains and smaller entities with only a few locations. Its expertise in complex energy markets and state regulations, coupled with a proven track record of helping clients achieve financial and operational goals, has earned it a stellar reputation across several industries. While American GEG serves various sectors, its client base is predominantly in the hospitality industry, including restaurants and hotels. American GEG understands its client’s needs and employs a strategic, comprehensive energy plan, which may include either its exclusive 360 Energy Management Plan or Guaranteed Energy Savings Plan. “With our comprehensive guidance, we help our clients manage even the most unexpected challenges that can affect their operations,” says Randy Carrasco, CEO. By implementing these plans, American GEG provides clients with tailored energy solutions for both short-term and long-term goals across multiple sectors, allowing them to optimize energy usage, reduce costs and achieve sustainability goals.

CXO INSIGHTS

Navigating the Tides of Change in the Natural Gas Industry

Mark Reese, Vice President, U.S. Natural Gas Supply, Just Energy

Policies and technologies driving the clean energy transition in the U.S.

Brendan Andrews, VP of Sales, Energy, and Renewables, Bureau Veritas North America

Fulfilling Regulatory Compliance with Technology

Brett Adamcik, System Integrity and Reliability Director, CenterPoint Energy [NYSE: CNP]

Transforming the Green Tech Industry With Low Carbon Energy

M. Douglas Dagan, Vice President, Strategic Initiatives - Renewable Energy, Suburban Propane

Championing Strategic Leadership in Water and Forest Sustainability

Elvy Barton, Water and Forest Sustainability Senior Manager, Salt River Project

Strategic Initiatives for a Cleaner Energy Future

Ivon Louis-Letang, Energy Manager, Eversource Energy

Leading the Charge toward a Hydrogen-Powered Future

Steve Schueneman, Hydrogen Development Manager, Puget Sound Energy (PSE)

IN FOCUS

Powering Progress: Innovations in Natural Gas Compression

The natural gas compression sector is evolving through technological advancements and sustainability initiatives to enhance efficiency and reduce emissions.

Reinventing ESP Reliability with AI and Engineering

Advancements in Electrical Submersible Pumps enhance reliability through the use of innovative materials, fluid dynamics, and intelligent control systems, ensuring efficient resource extraction and proactive maintenance in challenging environments.

EDITORIAL

Rethinking ESP Reliability for a Harder, Deeper Future

As operators drill deeper into more hostile conditions, downtime costs more than ever. Failure is no longer an inconvenience. It risks high-value wells, drives up intervention costs and increases the carbon footprint every time a rig returns to fix the same problem.

New threats lurk in the electrical system. Harmonics, grounding issues and voltage spikes quietly erode reliability until a pump fails when needed most. Producers are moving from reactive to proactive by investing in smarter protection. Surge suppression, harmonic filters and live monitoring are now frontline defenses.

Diagnostics have left the clipboard behind. Modern ESPs provide real-time data through intelligent sensors and SCADA-linked tools. Operators can see voltage, backspin and distortions without stepping near arc flash zones. Each insight adds days or weeks to an asset’s life and keeps crews safer.

This is not just about squeezing more barrels from a well. It is about building an infrastructure that can withstand complexity, protect investments and cut the hidden costs of failure. Market forecasts reflect this shift. The ESP systems market is set to exceed $16 billion by 2030, driven by reliability and risk mitigation.

Smarter ESPs bring fewer surprises, longer runs and smaller environmental footprints. The most resilient wells will succeed not just because of their depth, but because they protect what works far below the surface.

The magazine features thought leadership articles from Katie L. Morgan, Director of Natural and Cultural Resources at Partner Engineering & Science, who emphasizes the importance of environmental due diligence and early risk identification in major infrastructure projects, reinforcing the need for a holistic approach to asset reliability. Charles E. Venditti, Pipeline Integrity Manager at TRC Companies, discusses how pipeline operators respond to growing risk management demands, from corrosion control and data integration to planning for the next wave of CO₂ and hydrogen infrastructure.

We hope this edition provides meaningful insights and practical guidance for leaders driving progress in an ever-changing energy landscape.